VC OLP 4.8 sports a modern, user-friendly interface designed specifically for humans. You don’t have to be a robot to use it.

VC OLP is the #1 parametric and feature-based offline programming software for welding robots, and here’s what makes it different:

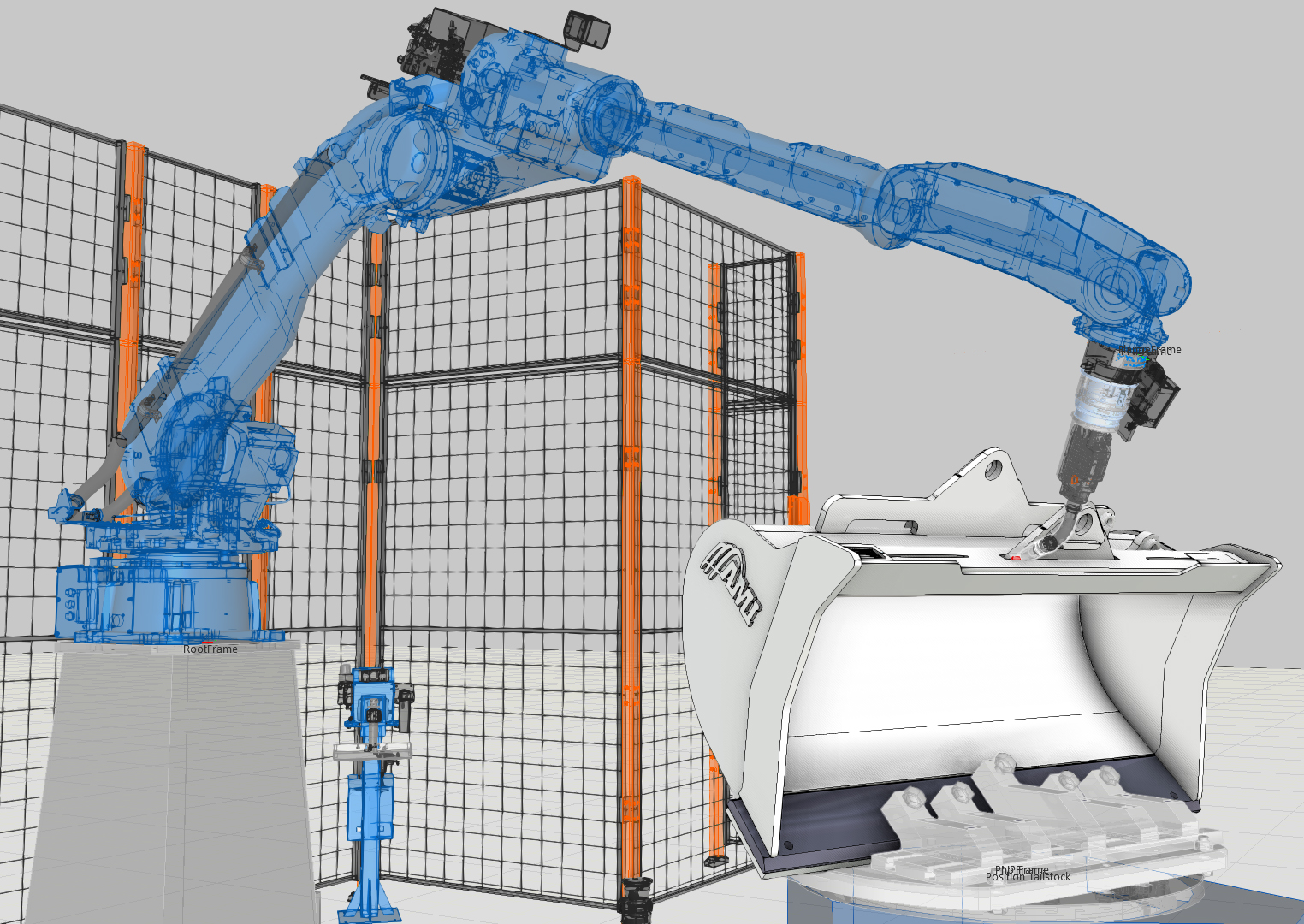

Traditional robot programming takes 8+ hours per new part, done point-by-point on the production floor using teach pendants. For job shops getting orders for 10 tables today, 15 buckets tomorrow, and custom brackets next week, this approach kills productivity.

Your expensive robot sits idle while you could have finished the job by hand. It’s not worth it—until now.

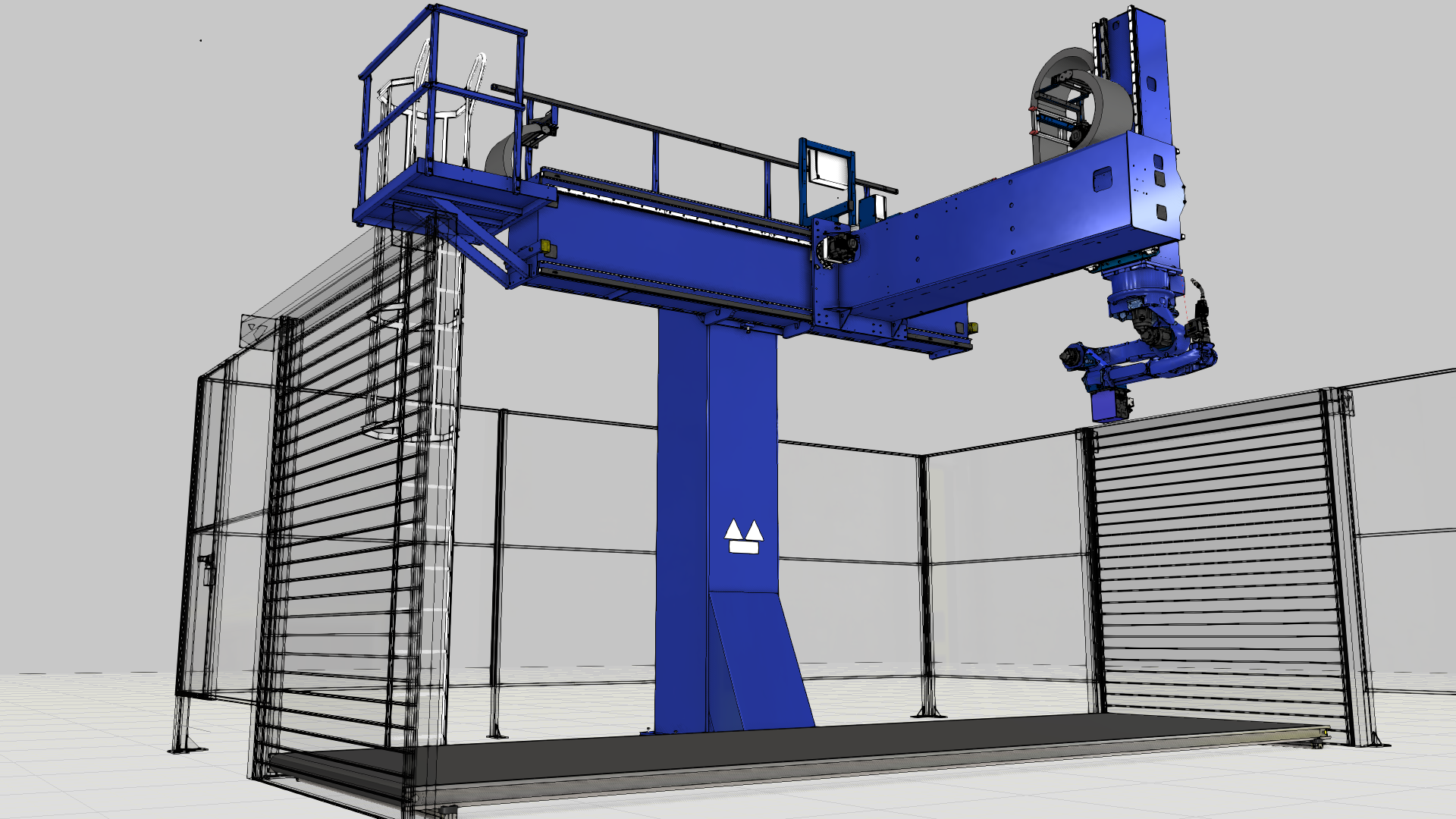

Turn weeks into minutes. Professionals program faster with VC, fully utilizing the incredible breadth of welding functionality. Every day, our customers benefit from getting a program to the machine more quickly than ever before.

High-mix, low-volume welding automation is now possible because you can create programs offline in under an hour while your robots keep welding previous jobs.

VC Robotics automatically handles the three major hurdles that slow down robot programming:

These three automatic features address the most common technical challenges that make traditional robot programming time-consuming and require specialized expertise to resolve manually.

Bring Parts In Directly From CAD. VC OLP supports all major 3D CAD formats, including STEP, SolidWorks, Inventor, ProE/Creo, IGES, CATIA, STL, DXF, DWG, and many others. Import your parts directly from CAD.

Don't settle for inadequate code or archaic software design. Delfoi supplies the most modern code to the latest CNC control versions, such as arc moves rather than hundreds of linear moves.

Add passes and offset for multi-pass welds. VC OLP lets you easily rearrange program order for heat management.

VC Robotics solves complex synchronous multi-robot motion and produces a single program. No sync issues or downtime for calibration or touch-ups due to multiple different programs.

Supported 3D CAD formats that work with your existing CAD files (no need to convert or recreate your designs):

• STEP

• SolidWorks

• Inventor

• ProE / Creo

• IGES

• CATIA

• STL

• 3D Studio (*.3ds)

• DXF, DWG

• ASCII Point Cloud file (*.xyz, *.pts, *.xyzrgb)

• Binary point cloud point (*.bxyz)

• Igrip/Quest/VNC geometry

• ASCII Stereo Lithography (*.stl)

• VMRL 1 & 2 (*.vrml, *.wrl)

• Tekla

• OpenNurbs – Rhino

• Medusa 3D

• CADDS

• Matra EUCLID 3, Straessle EUKLID

• I-DEAS

• ROBOCAD

• SAT: ACIS

• Sketchup (*.skp)

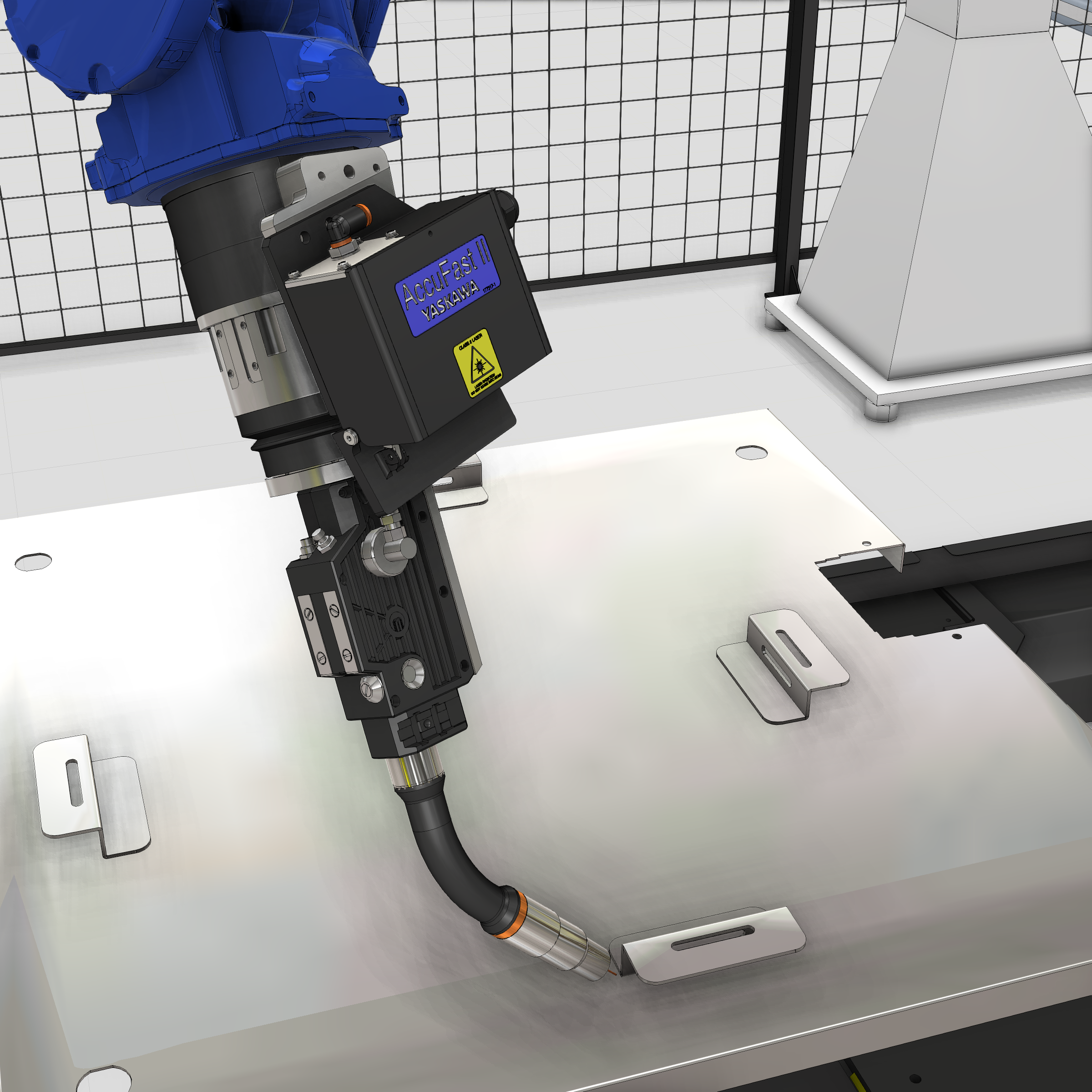

Robot Brand Compatibility: Over 1,500 models are supported by all major manufacturers, including Yaskawa, ABB, KUKA, Fanuc, and others.

Mach Machines is a welding-focused robotic integrator that makes advanced automation accessible to fabricators of all sizes. While most integrators are generalists, we’re welding specialists who lead with the latest technologies to give you programming independence.

Our complete automation solutions include:

VC Robotics OLP software is the foundation that makes all of these solutions work for high-mix, low-volume production.

Join the hundreds of companies switching to VC Robotics OLP for their offline solution to robotic welding programming. Stop wasting time with teach pendants and start programming the way modern fabricators should.

Yes, VC Robotics OLP works with over 1500 robot models from all major brands, including Yaskawa, ABB, KUKA, Fanuc, and others. You don’t need to replace your existing welding robots to benefit from offline programming—the software is designed to work with the equipment you already have.

4460 Lake Forest Drive, Suite 210

Cincinnati, Ohio 45242

© 2025 Mach Machines