Systems designed around your specific needs, from large-scale gantries to pre-engineered.

You control your own robot programming with our offline software, eliminating dependence on integrators for ongoing production changes.

We lead with the latest offline programming software and vision-based seam tracking while competitors stick with outdated teach-pendant methods.

Complete service from concept to cycle-start, plus training and ongoing support.

From custom gantry systems handling massive parts to versatile cells for diverse production runs, see how fabricators across industries have transformed their operations with custom automation solutions from Mach Machines.

3-Axis gantry, multi-station servo adjustable span head/tail stock positioners, stainless steel welding

Block welding, shipbuilding, extremely large parts – custom engineered portal gantry formats can accommodate nearly any size weldments.

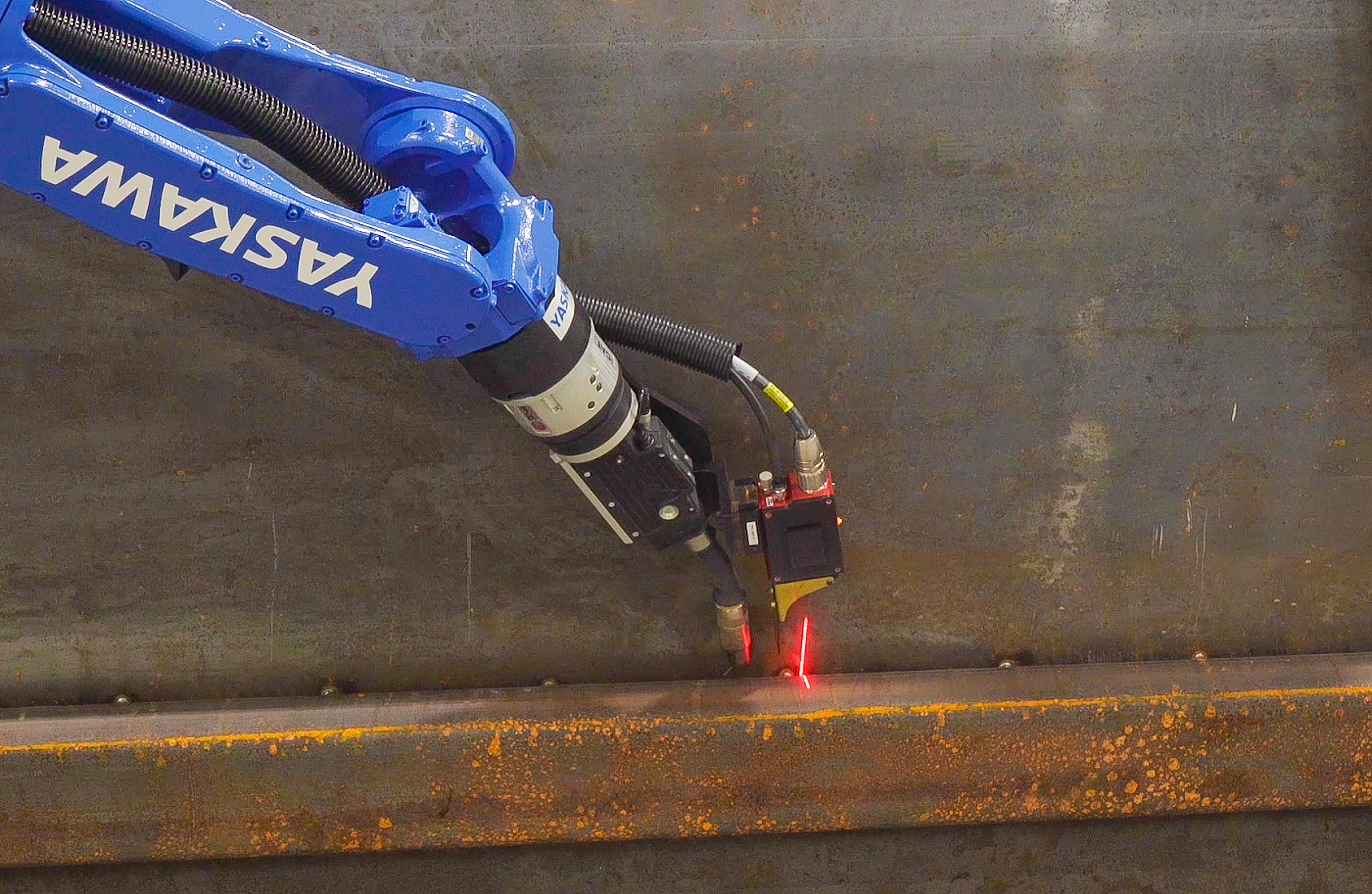

Mach Machines integrates and retrofits ServoRobot solutions onto new or existing welding robots for next generation vision-based seam tracking.

Proven results across diverse industries. Professional fabricators worldwide trust Mach Machines, including:

Traditional robot integrators focus on high-volume manufacturers running the same part thousands of times. But what happens when you get orders for 10 tables today, 15 buckets tomorrow, and custom brackets next week?

Conventional robot programming takes 8+ hours per new part, done point-by-point on the shop floor. Your expensive robot sits idle while your welders could finish the job by hand. It's not worth it.

Advanced offline programming software that changes everything. Create robot programs in your office in under an hour while your robots stay in production. When the new job arrives, simply load the program and start welding.

Most integrators haven't figured out that offline programming is the future. They're still stuck in the old teach-pendant method that only works for high-volume production. We've been perfecting this technology while they've been ignoring the job shop market.

High-mix, low-volume automation is now viable. Your robot stays productive, your ROI works, and you can finally compete with the efficiency you've been dreaming about.

Application-first engineering for projects others won't take on. From complex gantry systems for large-scale parts to multi-robot cells with vision-based seam tracking. If your welding challenge seems impossible, we specialize in making it possible.

Learn More

Ready-to-deploy automation for faster implementation. Our Mach 2000 systems and ArcWorld series offer elevated safety standards, advanced controls, and built-in offline programming capability—all at a lower cost entry point into welding automation.

Learn More

The game-changing software that enables high-mix, low-volume production. Program your robots offline in minutes, not hours, while keeping your production running. Works with 1500+ robot models from all major brands.

Learn More

True white glove service from crate to cycle-start. Complete installation, custom PLC programming, comprehensive training, and ongoing support. Unlike competitors who bolt a robot to your floor and disappear, we're with you every step of the way to make sure your automation actually works.

Learn More

Whether you need a large-scale custom system or an entry-level automation cell, we’ll do it all. You get the software tools to maintain programming independence moving forward.

We start by understanding your specific application needs and the challenges other integrators have told you can't be solved.

We design systems around your specific needs, from large-scale gantry systems to multi-robot cells with advanced vision tracking capabilities.

We handle complete system integration with your existing equipment and processes, including custom PLC programming and safety systems.

Our "crate to cycle-start" installation includes complete system commissioning and testing to make sure everything works before you start production.

We provide comprehensive training on robot operation and VC Robotics OLP software so you maintain complete programming independence.

Contact Mach Machines today to explore how we can solve your welding challenges and boost your competitive edge.

4460 Lake Forest Drive, Suite 210

Cincinnati, Ohio 45242

© 2025 Mach Machines